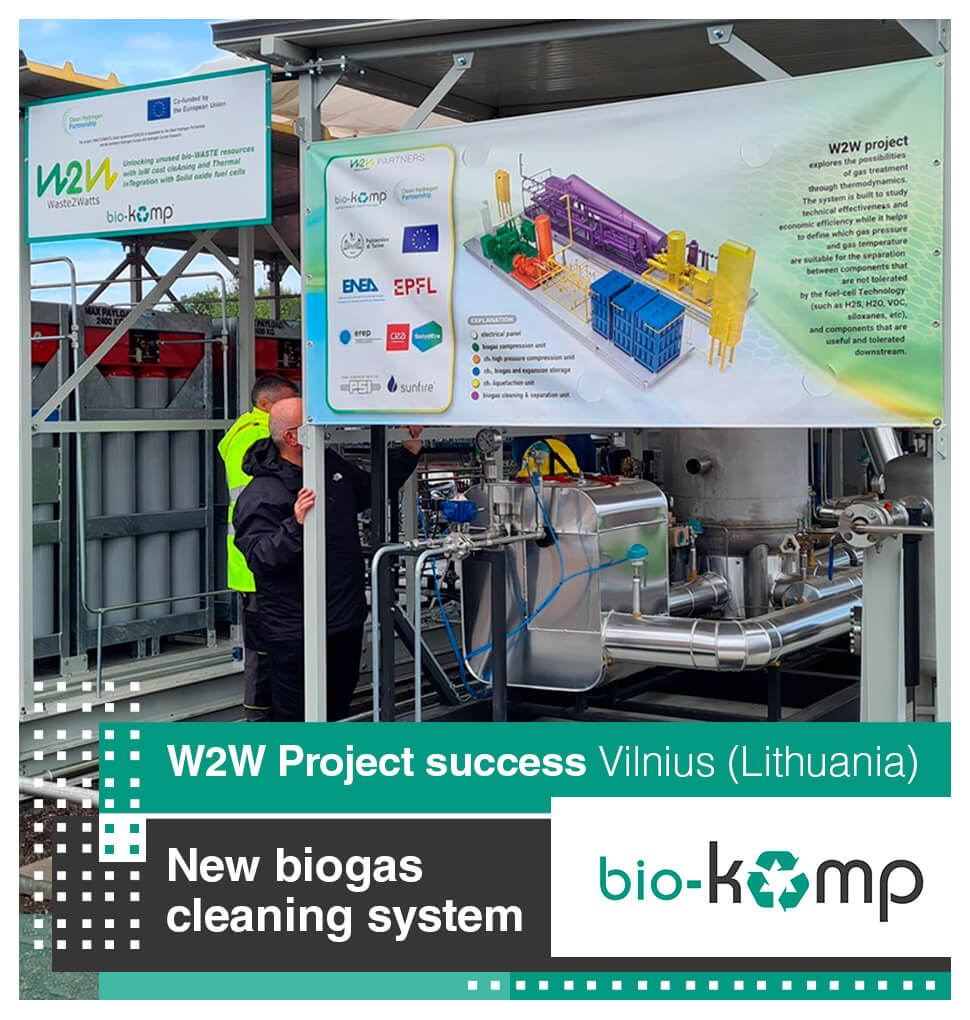

Biokomp: Biogas treatment plant

15 February 2024 - Solutions, CorporateBiokomp, a Pietro Fiorentini Group company, is one of the leading producers of complete packages for natural gas, biogas, biomethane, air and process gas compression & treatment plants of all sizes as well as special components.

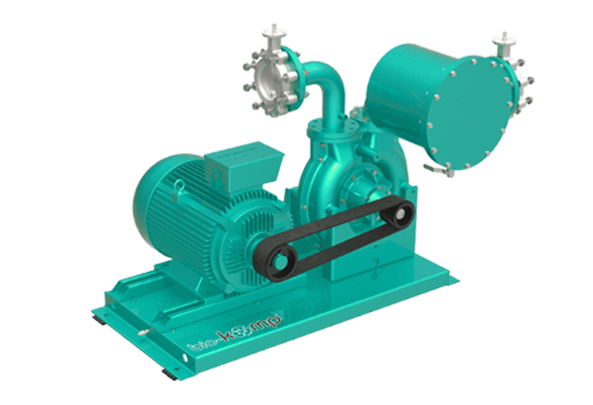

The Pietro Fiorentini Group company manufactures compression plants for natural gas, biogas, biomethane and industrial gases. Biokomp can provide different types of gas compressors and blowers: centrifugal, rotary screw, and piston.

Performances and reliability are guaranteed by custom-designed projects according to the needed application. Biokomp solutions also also an extended technical support that starts from the feasibility study to the final commissioning, combined with an aftersale qualified assistance.

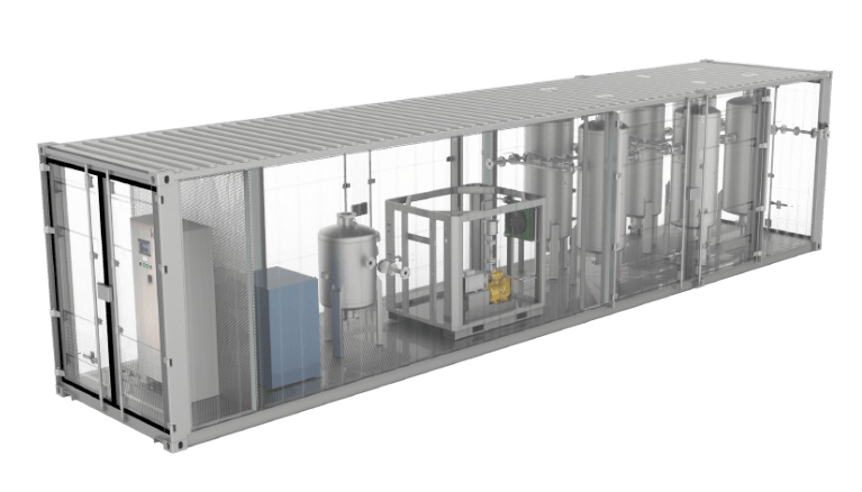

Biokomp solutions are available in different structures (open, closed, containerised) to allow maximum flexibility and integration with the industrial plants they are intended for, designed and built to withstand the most challenging climatic conditions. The Company’s strenght lies in providing strategic and optimised solutions for both conventional and special gas applications, particularly in the renewable energy generation and sustainable industry sectors.

BIOKOMP PRODUCTS & SOLUTIONS

GAS COMPRESSORS

Biokomp is specialised in designing and manufacturing low, medium and high pressure compressors for several gas types and different applications, including explosive and flammable fuels, hydrogen and light gases, using both oil-lubricated and oil-free technologies.

Compressor packages are available for hazardous (ATEX zone 1 and 2) and EX-proof installations.

We can provide the following compression ranges:

- LOW PRESSURE -0.5 ÷ 1 bar(g)

Different boosting equipment for air and gas applications: side channel blowers, multistage centrifugal blowers, vacuum pumps and rotary vane compressors. Also available with ATEX-rating. – Pressure range: -500 ÷ 1000 mbar(g). - MEDIUM PRESSURE 0 ÷ 25 bar(g)

Rotary screw compressors, fully packaged with instruments and automation control system, available for air, natural gas, LPG, biogas and industrial gases (EX-rated and NON-EX-rated). Pressure range: 0 ÷ 25 bar(g). - HIGH PRESSURE 0 ÷ 500 bar(g)

Modular and scalable piston compressors for CNG, biomethane and other gases. We develop tailor-made solutions including all gas processing components, such as gas dryer and filter systems, storage units, and refuelling equipment. Pressure range: 0 ÷ 500 bar(g).

BIOMETHANE EQUIPMENT

In biomethane plants, our Biokomp products can be successfully employed to allow biogas treatment and compression before and after upgrading, either to allow injection of biomethane into the natural gas grid or to use it as a vehicle fuel.

Reliability and performance of our equipment are essential not only to achieve the quality standards for natural gas, but also to ensure maximum energy efficiency and heat recovery.

CLEAN-UP AND DRYERS

Our extensive Biokomp post compression portfolio includes: High quality purification systems, fine particle filtration, drying units with condensate removal, gas refrigeration and heating with precise control of the gas temperature at discharge, and much more.

Find the right gas equipment and information in our product configurator.

Biokomp compressor stations include post-compression treatment units, such as cyclone filters, coalescing filters, dryers and chillers with condensate drainers which remove liquids, dirt, particles, and other impurities from the compressed gas. Condensate is removed automatically from the gas and conveyed to the outlet so to be safely disposed.

The post-compression treatment solutions can range as specified below:

- DEHUMIDIFICATION

Gas refrigerant dryers and water chillers specially designed for operation with air, acid, flammable and toxic gases. Stainless steel heat exchangers with automatic drainers. Dessiccant adsorption dryers with activated alumina, silica gels, and molecular sieves. - HEAT RECOVERY

Economizers and heat exchangers designed to recover the compression heat and make it available to an external fluid. Available in different materials and sizes. Tailor-made systems with different temperature and flow options. - OIL REMOVAL

Ultra-fine oil particulate filters and special activated carbon filters for oil removal up to 0,01 mg/m³, according to ISO 8573 requirements for oil-free gases. - GAS CONDITIONING

Post-compression gas conditioning skids, designed to control the gas temperature at discharge within a narrow tolerance range. Complete units with oil heat recovery, heat carrier pump, and programmable temperature control logic.

ATEX-RATED BLOWERS

Available in a range of different sizes, all blowers are in compliance with the ATEX directive, to be used in explosion protection zones.

Our systems are designed to stand even the most challenging climate conditions, from desert sand storms to the icy winds of Siberian remote regions.

All Biokomp systems can be housed in different enclosures, according to the specific installation needs. From simple skids to fully-equipped containers, we can design and provide the right solution for your project.

All Biokomp systems can be housed in different enclosures, according to the specific installation needs. From simple skids to fully-equipped containers, we can design and provide the right solution for your project.

BIOKOMP CASE STUDIES

COKE OVEN GAS RECOVERY

Boosting steelmaking efficiency: In order to use the process gas into a 2MW steam boiler, we have recently supplied a gas booster with knock-out drum for fine filtration of solid contaminants and temperature control system to cool the gas at the temperature required by the burner.

Client: ArcelorMittal

Country: Bosnia

ArcelorMittal is the world’s largest steel company, with a presence in more than 60 countries. It has led the consolidation of the international steel sector, and is today considered the only truly global steel producer.

> Click here for more project details.

> Find out more about the case study in this link.

> Download the Industrial Gas Solutions data sheet.

> Visit the project in our EXPERTISE AREA.

BIOGAS UPGRADING

Pioneers in biomethane production: Biokomp has provided the biogas treatment and compression for the first biomethane plant in Italy already in 2014. Our systems can be applied to different upgrading technologies (membrane, scrubbing, PSA) as well as direct injection of biomethane into the grid.

Client: GM – GREEN METHANE

Country: Italy

GM has developed a proprietary and proven technology for the upgrading of the Biogas to the Biomethane which core step is the CO2 removal

from the Biogas.

GM take advantage from the specific and synergic background of the partners in the design, construction, operation and maintenance of industrial plants.

> Click here for more project details.

> Find out more about this case study in this link.

> Download the Biomethane Solutions data sheet.

> Visit the project in our EXPERTISE AREA.

BIOGAS COGENERATION WITH TURBINE

Biokomp offers a wide range of gas processing systems for microturbine applications with capacities ranging from 5 Nm3/h per hour to 5.000 Nm3/h. Our clean-up, dewatering and compression units are designed to operate with several fuel types (Natural gas, Wellhead gas, Associated Petroleum Gas, Biogas).

Client: LAIBACH DOO

Country: Slovenia

Founded in 1992 as a family business and originally focused on the distribution of industrial semifinished products, Laibach has been connected with customers active in power distribution and research institutes since its inception.

Laibach’s team provides project planning, installation supervision, start-up, and maintenance of Capstone products, ensuring turn-key solutions within Slovenia and Croatia.

> Click here for more project details.

> Find out more about this case study in this link.

> Download the Natural Gas Solutions data sheet.

> Visit the project in our EXPERTISE AREA.

BIOGAS COGENERATION WITH ENGINE

Our compressor series for CHP gas engines stands out for reliability, high efficiency, and easy maintenance, making them a perfect fit for your power generation project. Discover the unique advantages of Biokomp compressors, which combine high quality materials and special coatings to meet the heavy-duty requirements of an industrial power plant.

Client: SPUMADOR

Country: Italy

Spumador S.p.A. is a producer of carbonated soft drinks. Founded in 1888 in Cermenate, in the province of Como, Domenico and Regina Verga started the production of carbonated soft drinks.

Today, the Como-based group has more than 400 employees and a total of four bottling plants for 22 production lines.

> Click here for more project details.

> Find out more about this case study in this link.

> Download the Biogas Solutions data sheet.

> Visit the project in our EXPERTISE AREA.

More information about Biokomp in our PF Group Companies & Brands page.

VISIT PIETRO FIORENTINI EXPERTISE IN BIOMETHANE